How to Choose Mushroom Head Carriage Bolts for Your Projects?

When it comes to selecting the right fasteners for your projects, understanding the nuances of Mushroom Head Carriage Bolts is essential. According to a recent industry report by Fastener World, these bolts account for over 25% of fastener usage in construction and woodworking. As noted by expert John Thompson, "Choosing the right type of bolt can significantly impact both the integrity and aesthetics of your work."

Mushroom Head Carriage Bolts are known for their unique design. Their rounded heads provide a clean finish and distribute load effectively. However, selecting the wrong size or material can lead to failures and safety issues. Reports indicate that inadequate fastener choices increase project costs by approximately 15% due to rework and delays.

Despite their benefits, many overlook the importance of compatibility with various materials. This oversight can affect joint strength and performance. A project is only as strong as its weakest link, and often, that link is the fastener. Understanding how to choose the right Mushroom Head Carriage Bolt can lead to better results and improved longevity of your projects.

Understanding Mushroom Head Carriage Bolts and Their Uses

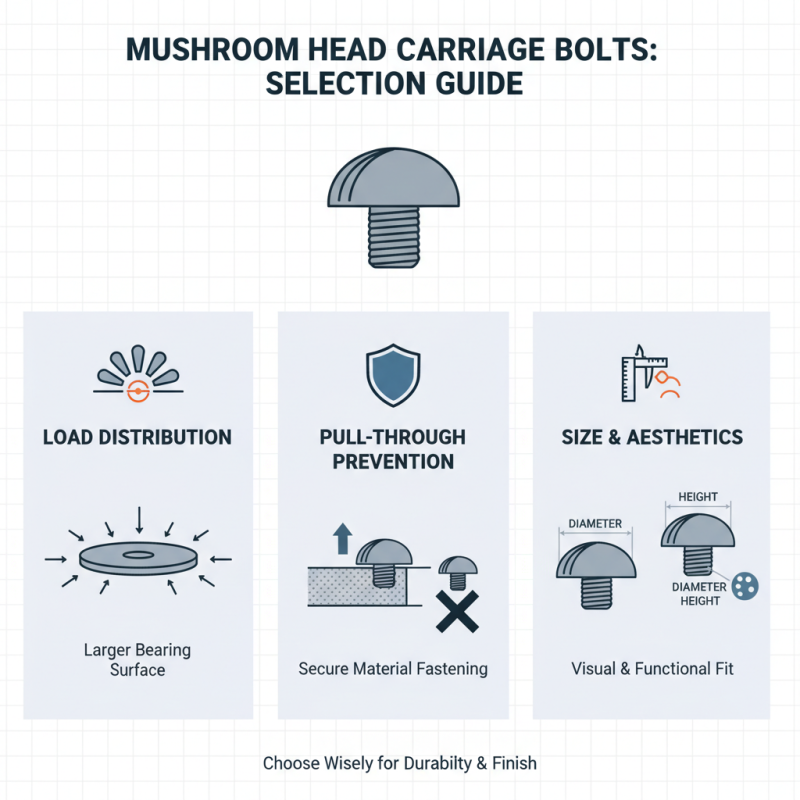

Mushroom head carriage bolts are versatile fasteners commonly used in various construction projects. Their unique, rounded head design allows for a broad bearing surface. This helps distribute the load evenly, reducing the risk of splitting wood or damaging softer materials. According to the Fastener Industry Association, proper bolt selection is critical to ensure structural integrity and longevity in projects.

These bolts are particularly useful in applications requiring flush surfaces. When installed, the mushroom head sits above the surface, providing a neat appearance. It's essential to consider the bolt's diameter, length, and material. A report from Machinery's Handbook highlights that corrosion-resistant options are available, which can extend the lifespan in outdoor settings. However, users often overlook the importance of matching the bolt material to the environment.

Installation can be tricky. Misalignment may cause the bolts to fail under pressure. Taking time to measure accurately before drilling is crucial. Some projects might require a specific torque to secure the bolts properly. Reports indicate that improperly tightened bolts contribute to over 30% of fastener failures. It's clear that choosing the right mushroom head carriage bolts can significantly impact project outcomes. That demands careful evaluation and standards adherence to achieve the desired results.

Mushroom Head Carriage Bolts Usage in Different Projects

Factors to Consider When Selecting Mushroom Head Carriage Bolts

Choosing the right mushroom head carriage bolts for your projects requires careful consideration of various factors. The head's shape is critical. A mushroom head provides a larger bearing surface, helping with load distribution. This design also minimizes the chance of the bolt pulling through materials. Pay attention to the diameter and height of the head, as these affect both aesthetics and functionality.

Material is another essential aspect. Steel bolts are common, but stainless steel offers great resistance to rust and corrosion. If your project is outdoors, this is a crucial choice. Think about the coating as well. Some may have a galvanized finish, enhancing durability. However, that added layer may also impact compatibility with other metals.

Finally, consider the length of the bolt. It needs to be just right—not too long to cause protrusion issues, nor too short to compromise joint strength. Always measure your material thickness first. It's easy to overlook this detail, but it can lead to project delays. Take your time to weigh all these elements. It can feel overwhelming, but getting this right is essential for your project's success.

Materials and Finishes for Mushroom Head Carriage Bolts

When selecting mushroom head carriage bolts, materials and finishes play a vital role. Most commonly, these bolts are made from steel, stainless steel, or alloy materials. Each material offers unique benefits and drawbacks. For example, stainless steel is resistant to rust, making it ideal for outdoor projects. However, it is often more costly than regular steel.

A recent industry report indicated that more than 70% of construction professionals prefer galvanized steel for its durability. Galvanization adds a protective layer, which can extend the life of bolts by up to 50%. This is crucial for applications exposed to harsh environments. On the other hand, alloy materials are lightweight and strong but may not be suitable for every project due to potential cost limitations.

Finishes also impact performance and appearance. A smooth finish may reduce friction when bolting down components, yet it can accumulate dirt. An alternative is a textured or coated finish, which provides better grip but may not be as easy to clean. Each choice demands careful consideration. Balancing strength, durability, and aesthetics can lead to better long-term results in your projects. The selection process is essential, as the wrong choice can compromise structural integrity and increase maintenance needs down the line.

How to Choose Mushroom Head Carriage Bolts for Your Projects? - Materials and Finishes for Mushroom Head Carriage Bolts

| Dimension | Material | Finish | Common Applications |

|---|---|---|---|

| 1/4" x 2" | Steel | Zinc Plated | Woodworking, Carpentry |

| 5/16" x 3" | Stainless Steel | Passivated | Outdoor Furniture, Decking |

| 3/8" x 4" | Carbon Steel | Black Oxide | Heavy Machinery, Industrial Applications |

| 1/2" x 6" | Aluminum | Anodized | Lightweight Structures, Electronics |

| 3/4" x 8" | Bronze | Natural Finish | Boat Building, Marine Hardware |

Sizing and Length Requirements for Your Projects

When selecting mushroom head carriage bolts, sizing and length are crucial. The diameter of the bolt impacts its load-bearing capacity. A standard carriage bolt generally ranges from ¼ inch to 1 inch in diameter. For heavier loads, consider bolts above ½ inch. According to a study by the Fastener Technology Institute, proper sizing is essential. Using the wrong size can lead to structural failures.

Length is equally important. A common length range is between 1 inch and 10 inches. The required length often depends on the thickness of the material being fastened. For example, if you're working with a 2-inch thick wooden beam, a 3-inch bolt would provide adequate grip. However, if the bolt is too long, it may protrude excessively. The National Fastener Distributors Association highlights that excessive protrusion can create safety hazards.

In practice, measuring accurately is key. Tools like calipers and tape measures help ensure precision. Skipping this step can result in mistakes. Research shows that nearly 30% of hardware failures stem from incorrect sizes. Always reassess your requirements before selection. Seeking advice from experienced professionals can mitigate risks. This can enhance the overall integrity of your project.

Common Applications and Best Practices for Using Mushroom Head Bolts

Mushroom head carriage bolts are versatile fasteners used in various projects. Their rounded, flared head offers a wide bearing surface, making them ideal for applications requiring a secure grip. Commonly, they find use in deck construction, furniture assembling, and outdoor equipment. According to industry data, these bolts can hold significant amounts of load, often up to 80% of their tensile strength, when installed properly.

When using mushroom head bolts, consider the material. Stainless steel is a popular choice due to its resistance to corrosion. Aluminum options provide lightweight solutions, while carbon steel is often more economical. Each material has its pros and cons based on environmental conditions and load requirements. Also, take care in selecting the right length. A bolt too short won’t create a secure joint, and one that’s too long can weaken the fixture.

Tips: Always pre-drill the hole for easier installation. This prevents splitting in wooden applications. Regularly check for wear or rust in existing installations. If you notice any damage, replacing the bolts promptly is key. Remember, the fit between the bolt and the material is crucial for durability. Use washers when needed to distribute the load evenly.

Related Posts

-

Top 10 Uses of Carriage Bolt in Construction and DIY Projects?

-

Unlocking Industry Trends: Mushroom Head Screws at the 138th Canton Fair 2025

-

Exploring the Benefits of Using High Tensile Carriage Bolts for Your Construction Projects

-

How to Choose High Quality Carriage Bolts for Your Projects in 2025

-

How to Use Truss Head Carriage Bolt Effectively?

-

How to Choose the Right Carriage Bolt for Your Next Project