How to Choose Custom Carriage Bolts for Your Project?

When embarking on a project that requires Custom Carriage Bolts, it’s crucial to make informed choices. These fasteners are more than just metal pieces; they play a vital role in structural integrity. Custom Carriage Bolts come in various sizes and finishes, each suited for different applications.

Selecting the right bolt can greatly impact your project’s success. Consider factors such as the material of the wood or metal you are working with. The bolt length and diameter also matter, influencing strength and stability. However, avoiding hasty decisions is equally important. A common mistake is undermining the need for precision.

Additionally, Custom Carriage Bolts should match the aesthetics of your project. Think of the finishes available, like galvanized or black oxide. Reflect on how these choices affect both functionality and appearance. Keep in mind, every decision counts. Aim for a balance between practicality and style in your selection process.

Understanding the Basics of Custom Carriage Bolts

Custom carriage bolts play a crucial role in various projects. Understanding their basic components is key to selecting the right ones. These bolts consist of a rounded head and a square shank, which stops rotation during installation. This design ensures a secure grip in wood and other materials, preventing loosening over time. According to a recent report by the Fastener Technology International, custom bolts account for 30% of the fastener market, highlighting their importance.

When choosing carriage bolts, consider material and size. Steel and stainless steel are common materials, each offering different levels of corrosion resistance. In projects exposed to the elements, using stainless steel can provide durability. A study by the Industrial Fasteners Institute indicates that improper sizing leads to 15% of project delays. Thus, measuring accurately is essential to avoid costly mistakes.

Customizing your bolts can enhance performance. Options such as thread length and coating can improve their utility. However, the customization process has its challenges. Higher costs and longer lead times can be drawbacks. Careful planning and budgeting are necessary to ensure project success. Custom carriage bolts can meet specific needs but require thoughtful consideration.

Identifying the Material Requirements for Your Project

Choosing the right material for custom carriage bolts is crucial for project success. Different materials offer varying strengths and resistances. Steel is a common choice for construction, while stainless steel provides excellent corrosion resistance. According to the American Institute of Steel Construction, steel bolts can handle tensile strengths over 120,000 psi, making them suitable for heavy-duty applications.

When selecting materials, consider the environment where the bolts will be used. If the project is in a coastal area, choose materials that resist rust. Galvanized steel or stainless steel are good options for protecting against moisture. The National Association of Corrosion Engineers states that approximately 30% of bolt failures occur due to corrosion. This highlights the importance of material selection in environments prone to rust.

Reflecting on material requirements can prevent costly mistakes. It is easy to assume one material fits all. However, ignoring specific needs can lead to project delays. Seek guidance from industry standards and material specifications, as they provide valuable insights. Evaluating the environment, load requirements, and longevity can enhance project outcomes significantly.

Determining the Right Size and Length for Carriage Bolts

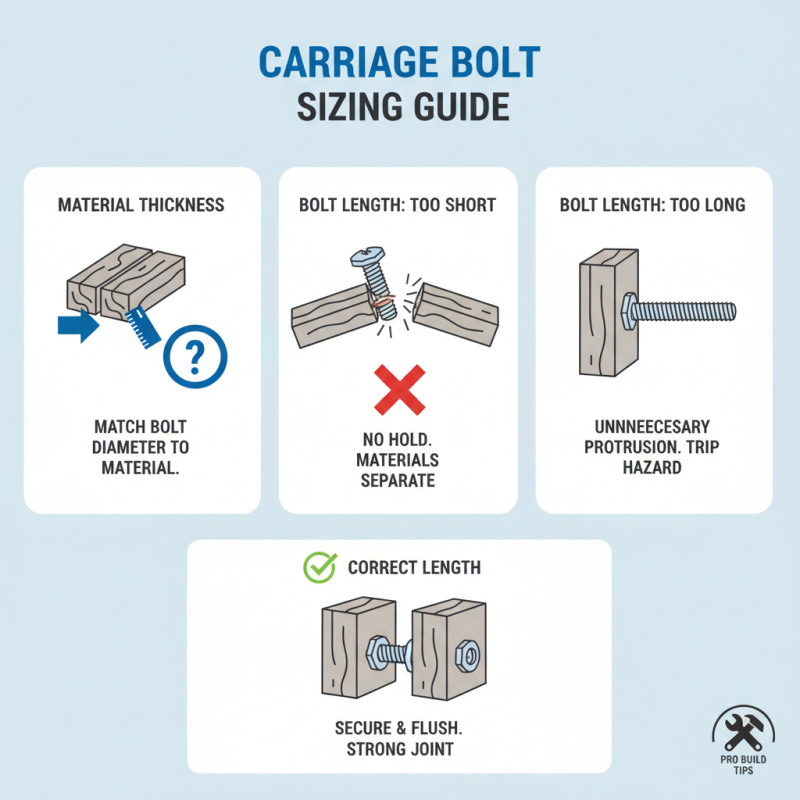

Choosing the right size and length for carriage bolts is crucial for the success of your project. The size of the bolt must match the thickness of the materials you are joining. For example, if you are working with a wooden beam, consider how deep the bolt should go. A bolt that's too long might protrude unnecessarily, while one that's too short won't hold. It's a balance that can take time to figure out.

You should also measure the diameter of the holes you're using. A bolt that is too wide will not fit well, and one that is too narrow can loosen over time. Keep in mind the strength of the material. Softer materials may need smaller bolts. A less-than-ideal choice can lead to structural weaknesses. Test different lengths and sizes before finalizing your decision. It often feels tedious, but it's worth the effort.

When selecting a bolt, remember to think about the nut and washer as well. Size discrepancies can create mismatches in fit and function. Take your time to ensure everything is compatible. It might feel overwhelming initially, but with careful measurements and adjustments, the right choices will emerge. Trust the process, and don’t rush it.

Selecting the Appropriate Finish for Durability and Aesthetics

When choosing custom carriage bolts, the finish is crucial. It can significantly influence durability and aesthetics. For instance, hot-dip galvanized bolts offer excellent corrosion resistance. A study by the American Galvanizers Association reports a service life of over 70 years in harsh environments. However, the finish can impact the final look of your project. Some finishes may not blend well with all design themes.

Another option is stainless steel, known for its strength and resistance to rust. A report from the Nickel Institute indicates that stainless steel can offer a 10-20% longer lifespan than traditional steel. Yet, stainless steel's bright appearance may not suit every application. For wooden projects, consider powder-coated finishes for enhanced durability. These can resist chipping and fading, ensuring longevity and maintaining aesthetics.

Every project has unique needs. A wrong finish choice could be costly. Understanding the finish's impact is essential for achieving your project's goals. Take time to evaluate the environment and intended use. Balancing beauty and functionality is key, but not easy.

Durability and Aesthetic Ratings of Finishes for Custom Carriage Bolts

Evaluating Supplier Options for Custom Carriage Bolts

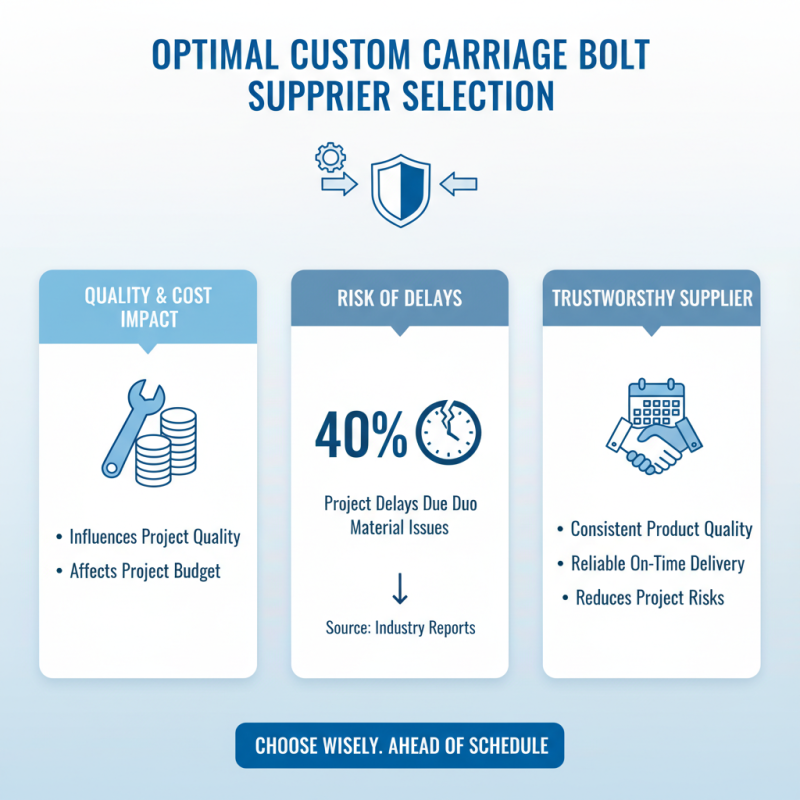

When evaluating supplier options for custom carriage bolts, several factors come into play. A reliable supplier can influence both the quality and cost of your project. According to industry reports, nearly 40% of project delays are due to material-related issues. This emphasizes the importance of selecting a trustworthy supplier who can consistently deliver quality products on time.

One key aspect to consider is the supplier's production capabilities. Do they have the necessary machinery to handle your specific requirements? Custom carriage bolts can vary widely in size and specifications. Ensuring that a supplier can produce to your exact specifications is crucial. Additionally, look for suppliers that have a strong track record. Over 60% of businesses report improved efficiency rates by choosing established suppliers.

Communication is vital too. A supplier should be responsive and willing to discuss issues openly. Many projects fail due to miscommunication about material specifications. Reviewing client testimonials can offer insights into how a supplier handles challenges. Not all suppliers will meet expectations, so conducting thorough research can save significant time and costs in the long run.

Related Posts

-

How to Choose the Right Stainless Bolts for Your Project Needs

-

How to Choose the Perfect Hot Sale Carriage Bolt for Your Project

-

What is a Hot Sale Carriage Bolt? Uses, Features, and Buying Guide

-

How to Select the Perfect Button Head Bolt for Optimal Load Distribution in Your Projects

-

What is a Custom Wood Screw? Types, Uses, and Benefits Explained

-

The Ultimate Guide to Choosing the Right Furniture Screw for Your Projects