How to Choose the Right Square Neck Bolt for Your Project?

Choosing the right Square Neck Bolt is critical for ensuring the success of your project. Square Neck Bolts are versatile and widely used in various applications. Their unique design allows for a secure grip, making them ideal in many situations.

When selecting a Square Neck Bolt, consider the material and size. Different materials serve different purposes, such as strength and corrosion resistance. The size must match your project needs. However, it's easy to overlook details when making a quick decision. A wrong size can lead to failure in your assembly.

Visualize your project's demands. For heavy-duty applications, steel might be necessary. For aesthetic purposes, a polished finish could be important. Yet, not every decision is straightforward. Sometimes, choices can be daunting. Reflect on what fits best, as a well-chosen Square Neck Bolt can significantly impact the outcome.

Understanding Square Neck Bolt Specifications and Standards

Choosing the right square neck bolt requires an understanding of specifications and standards. Square neck bolts come in different sizes and materials. Common materials include steel, stainless steel, and alloyed metals. Depending on your project, you may need a specific material for strength or corrosion resistance.

Tips: Always consider the load requirements. A heavier load may require a higher grade bolt. Pay attention to the bolt's diameter and length. These dimensions must match your application to ensure a secure fit.

Standard specifications, like ASTM A325 and A490, govern bolt manufacturing. These grades define minimum tensile strength and yield strength. For instance, A325 bolts have a minimum tensile strength of 120 ksi, making them robust for structural connections. Understanding these parameters ensures safety and performance in your projects.

Tips: Review any previous project failures. Reflect on what went wrong with bolt choices. It might save future headaches. Get familiar with common standards. These specs are crucial for reliable outcomes in construction and manufacturing scenarios.

Identifying Material Types for Square Neck Bolts: Pros and Cons

When selecting square neck bolts, material choice is critical. Common materials include steel, stainless steel, and brass. Each offers unique advantages and disadvantages for different applications.

Steel bolts are very durable and often cost-effective. However, they can corrode quickly in harsh environments. According to industry reports, about 40% of steel fasteners fail due to corrosion issues. This makes protective coatings or galvanization necessary, which adds to costs.

Stainless steel is resistant to rust and offers great tensile strength. It is ideal for projects exposed to moisture. However, stainless steel is pricier, which can impact budget decisions. A recent survey indicates that 30% of project managers factor material cost into their selections. Brass, while resistant to corrosion, is softer and less suitable for heavy loads. Understanding these trade-offs can help guide your bolt selection. Ultimately, consider your project’s specific conditions and the long-term implications of your material choice.

Material Types for Square Neck Bolts: Pros and Cons

Evaluating Load-Bearing Capacity and Size Requirements

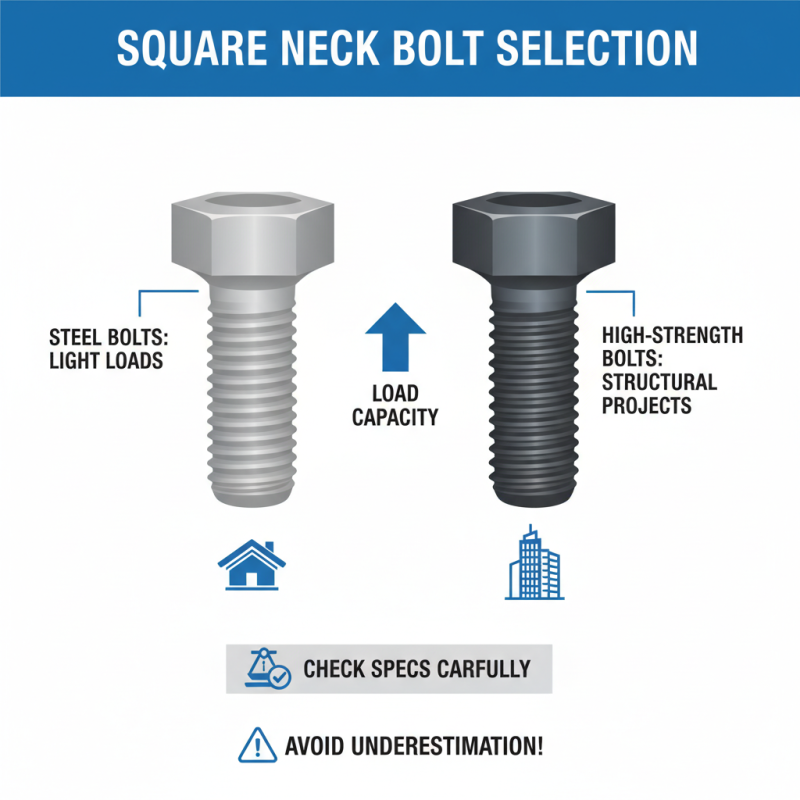

When choosing a square neck bolt, evaluating load-bearing capacity is crucial. The materials involved can greatly influence how much weight a bolt can handle. For lighter applications, steel bolts might suffice. However, for structural projects, consider high-strength bolts. Carefully check the specifications to avoid underestimating needs. A common mistake is assuming all bolts are equal.

Next, size requirements cannot be overlooked. Diameter and length are key factors. Too short a bolt won't provide adequate grip. Too long, and you risk damaging surrounding components. Measurements must be precise, yet many overlook this. Try using calipers or gauges for accuracy. Taking time to double-check sizes can save trouble later on.

The environment also matters. For outdoor projects, rust resistance might become a priority. Many forget this aspect, leading to premature failures. Balancing load capacity and right sizing is challenging. Reflecting on these details ensures a reliable choice. Always be prepared to adapt if initial selections don’t meet expectations.

Selecting the Right Coatings and Finishes for Durability

When selecting square neck bolts, the coatings and finishes play a crucial role in durability. According to a study by the American Society for Testing and Materials (ASTM), coated fasteners can last up to 50% longer than uncoated ones in corrosive environments. Proper coating enhances resistance to rust, environmental damage, and wear.

Tips: Consider the environment where the bolt will be used. If it’s exposed to moisture or harsh chemicals, a heavy-duty coating is essential.

Common coatings include zinc plating and powder coating. Zinc plating offers good corrosion resistance for indoor applications. However, it may not hold up well outdoors without additional protection. On the other hand, powder coating adds a tougher layer, ensuring better longevity against weather elements.

Many engineers overlook the potential for coating failures. It’s essential to examine the finish regularly. A chipped or worn coating can lead to faster deterioration than anticipated.

Tips: Always choose a finish based on specific project demands. Testing various coatings can uncover weaknesses you might not expect.

Comparing Cost-Effectiveness Across Different Square Neck Bolt Suppliers

When selecting square neck bolts, cost-effectiveness is crucial. Different suppliers offer varied prices. According to a recent industry report, suppliers with larger production capacities often provide better pricing. They can reduce costs due to economies of scale. However, lower prices may compromise quality. It's essential to balance cost and durability.

Manufacturing processes also impact pricing. Suppliers using advanced technology could charge more. The machinery can enhance accuracy, leading to fewer defects. Data shows that projects requiring high precision benefit from investing in quality. Consider the potential long-term savings from fewer replacements.

Some suppliers have hidden fees, such as shipping or handling. Compare quotes comprehensively. A lower initial price may result in higher overall costs. Evaluating the total price helps in making informed decisions. Each project has unique requirements. Reflect on how selecting the right supplier influences your budget and project success.

Related Posts

-

Understanding the Importance of Carriage Bolt Selection in Construction Projects

-

Why Choose Stainless Torx Screws for Your Projects?

-

Ultimate Guide to Stainless Carriage Bolt Types and Usage Tips

-

Top 10 High Tensile Carriage Bolt Benefits and Uses for Your Projects

-

2026 Top Stainless Carriage Bolt Uses and Benefits?

-

Exploring Button Head Bolts: The Unsung Heroes of Modern Engineering Applications