How to Choose the Right Stainless Bolt for Your Project?

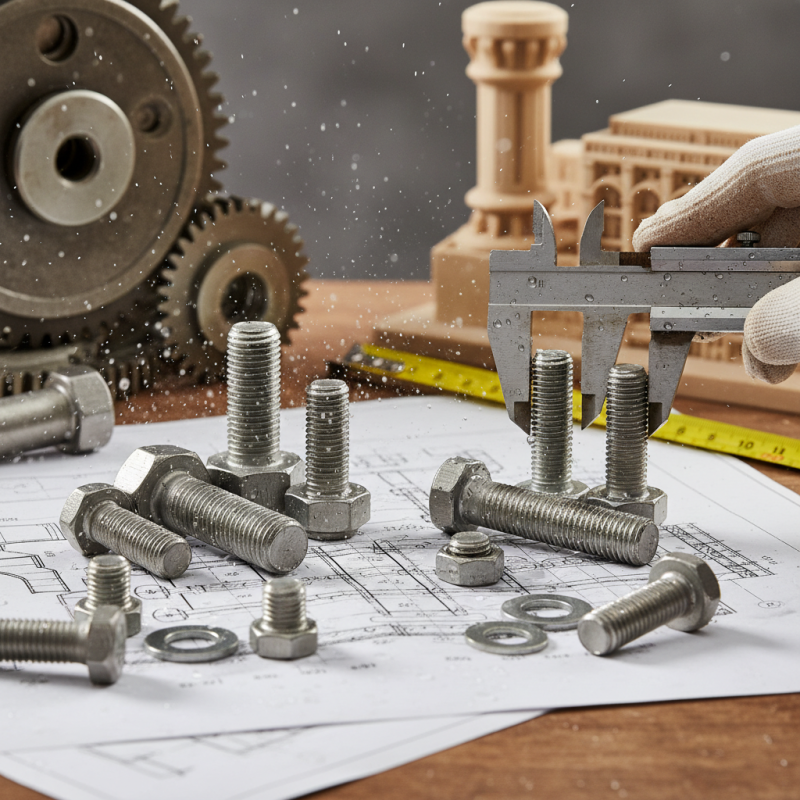

Choosing the right stainless bolt for your project is crucial. It affects strength, durability, and performance. Stainless bolts come in various grades and finishes. Each option serves different purposes. You need to consider the environment where the bolts will be used. Corrosion resistance may be a top priority in harsh conditions.

The type of project also matters. For heavy machinery, strength takes precedence. On the other hand, aesthetics might be more important in visible applications. Researching different grades of stainless steel is necessary. Common options include 304 and 316, but which one suits your needs?

Mistakes can happen if you rush this decision. Picking the wrong stainless bolt can lead to failure. Reflecting on the specific requirements of your project is essential. Attention to detail will ensure you make the best choice. Be mindful of the cost, but remember: quality matters. The right stainless bolt can make all the difference.

Understanding the Different Types of Stainless Steel Bolts Available

Choosing the right stainless steel bolt for your project starts with understanding the types available. Stainless steel bolts are commonly categorized into grades. Each grade has unique properties that affect performance.

For example, grade 304 is among the most common. It offers good corrosion resistance and is often used in indoor applications. However, it may not be ideal for harsh environments. On the other hand, grade 316 provides improved resistance to saltwater. This makes it a better choice for marine projects.

There are also specialized bolts, such as those with a duplex structure. These combine austenitic and ferritic stainless steels. They provide even higher strength and corrosion resistance. However, they can be challenging to source and more expensive. Reflecting on your project's specific needs is crucial. Do you need strength, or is corrosion resistance a priority? Making the right choice requires careful consideration and sometimes, a bit of trial and error.

How to Choose the Right Stainless Bolt for Your Project?

| Bolt Type | Material Grade | Corrosion Resistance | Typical Applications | Strength (MPa) |

|---|---|---|---|---|

| Hex Head Bolt | AISI 304 | Good | Construction, Automotive | 515 |

| Socket Head Cap Screw | AISI 316 | Excellent | Marine, Chemical Processing | 575 |

| Lag Bolt | AISI 304 | Good | Wood Working, Framing | 450 |

| Carriage Bolt | AISI 316 | Excellent | Outdoor Structures, Decking | 500 |

| U-Bolt | AISI 304 | Good | Automotive, Pipe Support | 400 |

Key Factors to Consider When Selecting Stainless Steel Bolts

When selecting stainless steel bolts, several key factors come into play. The grade of stainless steel is paramount. Common grades include 304 and 316. Grade 304 offers good corrosion resistance, while 316 provides superior protection against saltwater and harsh chemicals. According to industry reports, using 316 can reduce maintenance costs by up to 40% in marine environments.

Thread type is another crucial aspect. Coarse threads provide better grip in softer materials. Fine threads enable greater tension and shear strength. However, fine threads may also be more prone to stripping. Evaluating the specific requirements of your project can guide this choice.

Environmental conditions should not be overlooked. Humidity, temperature, and exposure to chemicals affect bolt performance. A bolt suitable for dry environments might fail in damp conditions. Insight from industry studies shows that improperly chosen bolts lead to a 25% increase in project delays. This highlights the significance of careful selection.

Evaluating Strength and Corrosion Resistance in Stainless Bolts

When selecting stainless bolts, strength and corrosion resistance are crucial. Many projects demand bolts that can withstand heavy loads while also resisting rust. Stainless steel's chemical composition plays a significant role in these attributes. For instance, 304 stainless steel is commonly used for general purposes. It possesses good corrosion resistance, but it may not be ideal for marine applications.

On the other hand, 316 stainless steel offers superior resistance to saline environments. This option is often overlooked due to its higher cost. Yet, it provides durability under harsh conditions where corrosion is a severe concern. Not all projects require such high performance, though. Sometimes, opting for a lower grade can save costs but may lead to future complications.

Balancing strength and corrosion resistance is not always straightforward. You may find yourself unsure of the right choice. Consider the environment where the bolts will be used. Will they be exposed to chemicals or saltwater? Reflect on the long-term implications of your selection. Ignoring these factors can lead to premature failure of the bolts, causing frustration and additional expenses.

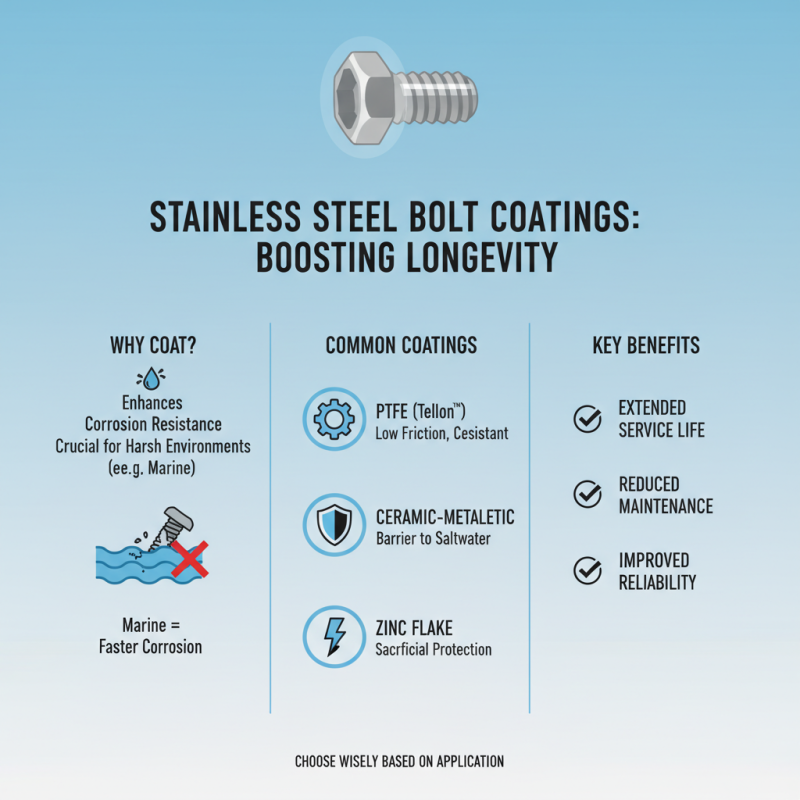

Selecting the Appropriate Coating for Stainless Steel Bolts

Selecting the right coating for stainless steel bolts is crucial for performance and longevity. Stainless steel offers good corrosion resistance, but depending on the environment, additional coatings may be beneficial. For instance, studies show that in marine environments, stainless steel can corrode faster. A coating can enhance protection against saltwater exposure.

One common choice is a zinc coating. It provides an extra layer of defense against rust and corrosion. Reports indicate that galvanized bolts can last up to 50% longer than uncoated versions in harsh conditions. Other options include epoxy and nylon coatings. These non-metallic coatings are excellent for reducing friction and preventing galling during installation. Yet, they can wear off over time. Regular inspections are necessary to assess their condition.

Consider environmental factors when selecting a coating. Temperature extremes can impact the performance of certain coatings. For example, temperature fluctuations can cause coatings to crack or peel. Proper assessment of the project’s specific needs is essential for long-term success.

Determining the Right Size and Thread Type for Your Application

Choosing the right stainless bolt for your project starts with understanding size and thread type. The diameter of the bolt is crucial. A bolt that is too small can’t handle the load. Conversely, a bolt that is too large may not fit into your assembly. Measure the hole carefully before making a decision.

Next, consider the thread type. Common options include coarse and fine threads. Coarse threads are easier to install and have better holding power in softer materials. Fine threads provide greater tension but require more effort to install. Think about the material you'll be working with, too.

**Tips:** Always take a sample bolt to the hardware store. Test different sizes to see what fits best in your application. If you’re unsure, consult with others or do a small test. It’s better to take more time than rush into an incorrect choice. This saves time later on and avoids potential project flaws. Remember, the right bolt can make a significant difference in stability.

Distribution of Bolt Sizes and Thread Types for Applications

This chart represents the distribution of various stainless steel bolt sizes and thread types used in different applications based on common industry standards.

Related Posts

-

Top 10 Stainless Bolt Types for Maximum Durability and Performance in 2023

-

How to Choose the Right Stainless Bolts for Your Project Needs

-

2025 Top Trends in Furniture Bolt Technology for Modern Home Designs

-

How to Choose the Right Truss Head Carriage Bolt for Your Project

-

How to Choose the Right Stainless Wood Screw for Your Next DIY Project

-

Understanding the Importance of Torx Screws in Modern Engineering