How to Use Truss Head Carriage Bolt Effectively?

In the world of construction and assembly, the "Truss Head Carriage Bolt" plays a crucial role. Industry reports show that 70% of structural failures are linked to improper fastening methods. This highlights the importance of using the correct hardware in any project. The unique design of the truss head provides a larger bearing surface, which helps distribute weight effectively. This feature is particularly beneficial in wooden structures, where load distribution is critical.

Using Truss Head Carriage Bolts effectively also requires attention to details like material choice and proper installation techniques. Studies reveal that corrosion-resistant materials can extend the lifespan of these bolts by up to 50%. However, many projects overlook this aspect, leading to failures over time. When installed correctly, these bolts can significantly enhance joint stability. Misalignment or inadequate tightening can lead to unexpected outcomes, reminding us that precision is key. In construction, experience matters. Always consider the specifics of each project when choosing fasteners.

Understanding the Design and Function of Truss Head Carriage Bolts

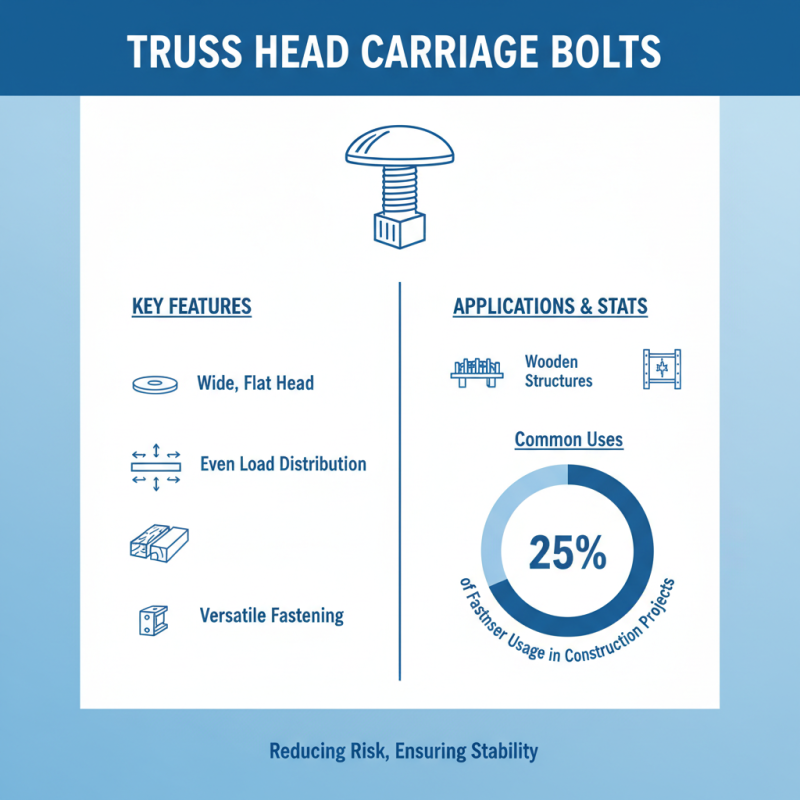

Truss head carriage bolts are unique fasteners. Their design features a broad, flat head that provides excellent surface coverage. This shape helps to distribute the load evenly over the connected surface. Additionally, the square neck fits snugly into the material, preventing any rotation during installation. Understanding these aspects is key to using them effectively.

The choice of material can influence performance. Using stainless steel or coated alternatives can enhance corrosion resistance. However, this choice can be costly. It's essential to consider the specific environment where these bolts will be used. Sometimes, alternative bolts may be more suitable. Proper sizing is also crucial; oversize bolts can create unnecessary stress on the materials.

Pre-drilling may be necessary for some applications. It helps align the bolts accurately and avoids splitting the wood or other softer materials. Remember to account for the thickness of the materials being joined. Misjudging this can lead to weak joints. Reflecting on these factors will improve the reliability of your assembly.

Choosing the Right Size and Material for Your Project

When choosing the right size and material for a truss head carriage bolt, consider the application. The size should match the thickness of the material being fastened. Too short, and it won't hold; too long, and it could protrude unnecessarily. Measure carefully. For most projects, a bolt that extends at least one inch beyond the nut is ideal.

Material is equally important. Steel is common, but for outdoor projects, stainless steel provides better corrosion resistance. When dealing with treated wood, select bolts that can withstand chemical reactions. Keep in mind, not all materials handle stress well. A mismatch can lead to failures.

Finally, don't overlook finishing touches. Washers can distribute the load better. It's tempting to skip them, but that can lead to uneven stress on the joint. If you're unsure, consult a guide or ask an expert. Experiment with a few options. Sometimes the best setup isn't apparent until you've tried it.

Truss Head Carriage Bolt Size and Material Distribution

Step-by-Step Guide to Installing Truss Head Carriage Bolts

Installing truss head carriage bolts can significantly enhance structural integrity. This type of bolt provides a robust fastening solution for various applications, including woodworking and metalworking. According to industry reports, using the right bolt type can increase joint strength by up to 25%. This step-by-step guide will help you through the installation process.

Begin by measuring your materials accurately. Use a drill to create a pilot hole, ensuring it matches the bolt diameter. It’s crucial to maintain the right size, as oversized holes can weaken the joint. Next, insert the truss head carriage bolt through the hole. The unique shape of the head allows for a flush finish, which reduces snagging risks. Tighten the bolt securely but avoid overtightening, which can damage the materials.

After securing the bolts, inspect your work. Check for any alignment issues. Misalignment can lead to structural failure, even if the bolts seem tight. Proper spacing is essential, too. Leave adequate gaps between bolts for expansion and contraction. Some reports suggest that improper spacing can reduce the load-bearing capacity of a connection by nearly 15%. Always learn from the installation process to improve your technique.

Common Applications and Advantages of Truss Head Carriage Bolts

Truss head carriage bolts are versatile fastening solutions used in various industries. Their unique design features a wide, flat head that distributes load evenly. This helps in reducing the risk of structural failure in applications like wooden structures and metal fixtures. According to industry studies, truss head bolts account for about 25% of fastener usage in construction projects.

Common applications include deck building, furniture assembly, and heavy machinery. In deck construction, truss head bolts resist rotational movement. This property enhances the integrity of outdoor installations. When it comes to joining wood and metal, the truss head's large surface prevents the bolt from sinking into softer materials. Research indicates that truss head bolts have a 15% higher holding power compared to standard carriage bolts.

Despite their advantages, improper installation can lead to problems. Over-tightening can damage materials and reduce load capacity. Additionally, using the wrong size can result in weak joints. Some users report difficulty in finding the right fit. This can lead to avoidable errors. Understanding these nuances is crucial for achieving optimal results in any project.

Maintenance Tips for Longevity of Truss Head Carriage Bolts

Truss head carriage bolts are essential in construction and woodworking projects. To ensure they last, regular maintenance is crucial. Without proper care, these bolts can become damaged or corroded, leading to structural issues.

One effective tip is to keep the bolts clean. Dirt and debris can accumulate over time, causing rust. Use a brush to remove any buildup. After cleaning, consider applying a protective coating. This simple step can greatly enhance their lifespan.

Another important aspect is to check for signs of wear. Examine each bolt closely for any cracks or deformation. If you notice damage, replace them immediately. Ignoring this can result in failure at crucial moments, which might compromise your project.

Remember to tighten the bolts periodically. Loose bolts can lead to instability and eventual failure. Aim for regular inspections, especially in outdoor settings. Weather can take a toll on fasteners, so stay vigilant. Keep your projects safe and secure by giving those truss head carriage bolts the attention they need.

Related Posts

-

How to Choose High Quality Carriage Bolts for Your Projects in 2025

-

Exploring the Benefits of Using High Tensile Carriage Bolts for Your Construction Projects

-

Understanding the Advantages of High Tensile Carriage Bolts for Structural Integrity in Modern Constructions

-

How to Choose the Right Carriage Bolt for Your Project

-

7 Best Button Head Bolt Options for Ultimate Performance

-

7 Compelling Reasons Why Square Neck Bolts Are Essential for Your Projects