Exploring the Growth of Torx Screw Demand at the 138th Canton Fair China 2025: Insights and Trends

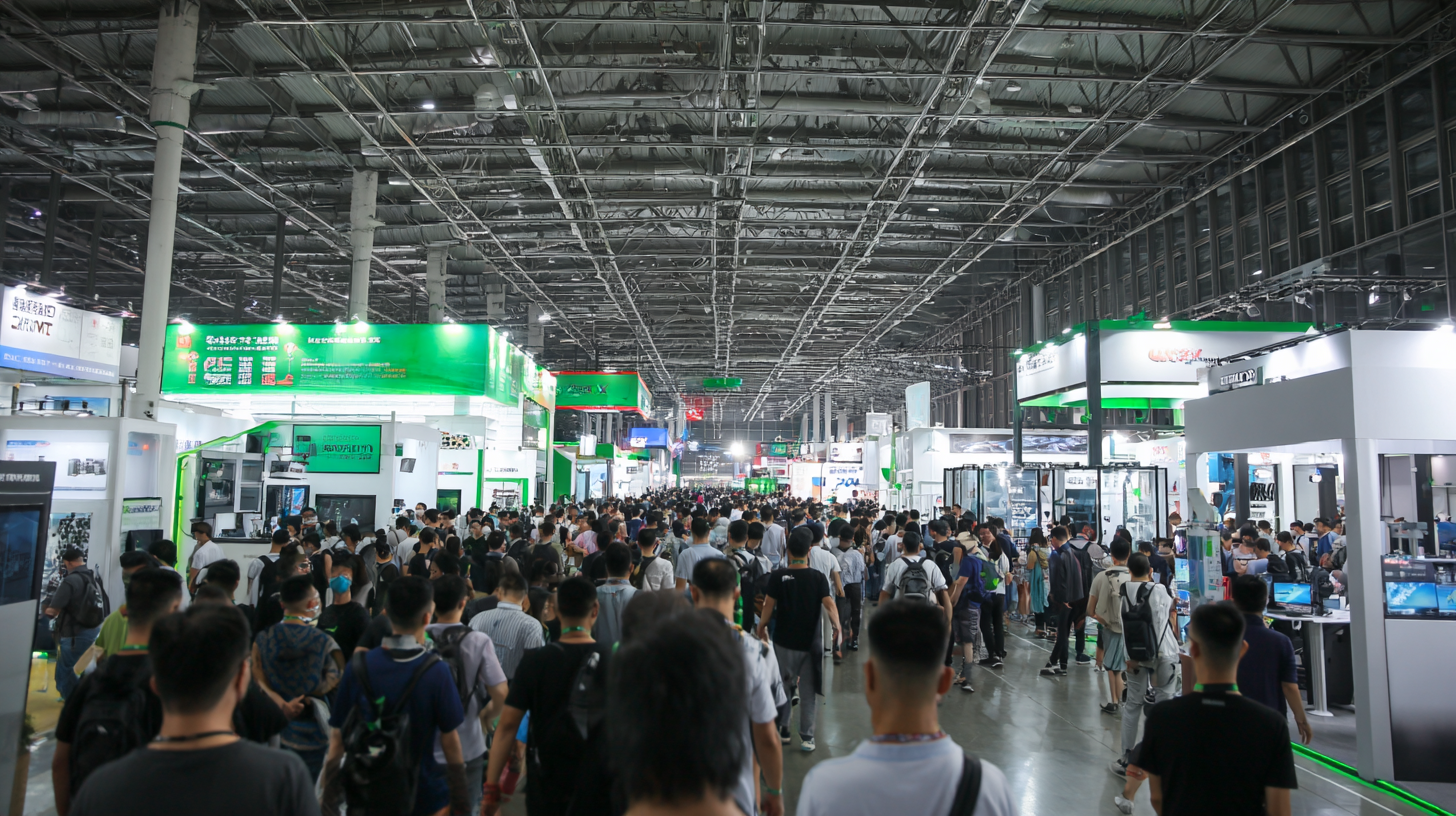

At the 138th Canton Fair in China, scheduled for 2025, a significant spotlight will be cast on the growing demand for Torx screws, a fastener type known for its unique star-shaped socket that allows for greater torque without damaging the screw head. As industries increasingly lean towards high-performance products, the adoption of Torx screws is expected to surge, driven by their advantages in automotive, electronics, and furniture manufacturing sectors. This year’s fair will not only showcase innovative applications of Torx screws but will also highlight emerging trends in the fastener industry amidst evolving market dynamics. Stakeholders from around the globe are anticipated to converge, offering a platform for discussions on the latest technologies, sustainability practices, and consumer preferences influencing the demand for Torx screws. By exploring these insights and trends, the 2025 Canton Fair promises to illuminate the trajectory of the fastener market and its alignment with broader industry advancements.

Emerging Trends in Torx Screw Applications for Industrial Growth

The demand for Torx screws is witnessing a notable surge, particularly in industrial applications. As manufacturers increasingly prioritize efficiency and durability, the unique design of Torx screws—characterized by their star-shaped drive—provides enhanced torque transfer and minimizes the risk of stripping. This makes them an attractive option for industries that require precision fastening, such as automotive, electronics, and construction. The 138th Canton Fair is expected to highlight these trends, showcasing innovative applications of Torx screws across various sectors.

Moreover, the rising trend of automation and robotics in manufacturing processes further fuels the Torx screw market. As machinery becomes more advanced, the need for reliable fastening mechanisms has grown. Torx screws are increasingly being integrated into automated assembly lines, where their performance contributes to lower maintenance costs and improved operational efficiency. Additionally, the expansion of electric vehicles and renewable energy solutions is paving the way for unique applications of Torx screws, emphasizing their role in the industrial growth narrative.

Impact of Technology Advancements on Torx Screw Design and Demand

The advancement of technology plays a substantial role in shaping the demand and design of Torx screws, particularly highlighted during the 138th Canton Fair in China in 2025. As industries transition towards more sophisticated engineering solutions, the Torx screw, known for its reliability and secure fastening capabilities, is experiencing a growing demand. Reports indicate that the global electric screwdriver market is projected to reach $1.53 billion by 2030, driven by trends in automotive and electronics sectors, which increasingly favor advanced fastening solutions like Torx screws due to their efficiency and performance advantages.

Moreover, the integration of innovative manufacturing technologies, including both cold feed and hot feed extruders, enhances the production quality of Torx screws while meeting varying industry needs. This shift not only boosts efficiency but also responds to the increasing push for lightweight and durable materials, essential for modern applications, particularly in electric vehicles. The Machine Screw Anchors market is also anticipated to see growth, with revenue projected to rise from $1.2 billion in 2026 to $1.8 billion by 2033, reflecting a compound annual growth rate (CAGR) of 5.0%. The interplay of these technological advancements and market demands underscores a pivotal transformation in fastening solutions, fueling future growth in the Torx screw segment.

Torx Screw Demand Growth Insights at the 138th Canton Fair China 2025

This bar chart displays the projected growth in global demand for Torx screws from 2019 to 2025, with significant increases attributed to technological advancements in screw design and industrial applications.

Key Market Players and Their Role in Shaping Torx Screw Demand

The demand for Torx screws is poised for significant growth, particularly highlighted during the upcoming 138th Canton Fair in China in 2025. Key market players are expected to play a pivotal role in influencing this trend, leveraging advancements in manufacturing technologies and responding to diverse consumer needs across various industries. As industries increasingly prioritize precision and efficiency, the unique design of Torx screws—known for their unique star-shaped head—offers advantages in torque transfer and reduced cam-out during fastening processes.

In the current market landscape, players in the screw manufacturing sector should focus on innovation and sustainable practices to attract a broader customer base. Tips for manufacturers include investing in R&D to enhance screw designs and materials, catering to specific industry requirements such as automotive or electronics. Additionally, aligning marketing strategies to emphasize the benefits of Torx screws over traditional fasteners can significantly boost their market presence.

As Torx screw adoption accelerates across multiple sectors, businesses must also consider forging partnerships and collaborations with end-users to better understand their fastening challenges. This approach not only fosters innovation but also ensures that product offerings meet the evolving demands of the market, ultimately solidifying the position of key players in shaping Torx screw demand.

Consumer Preferences Driving the Torx Screw Market Expansion

The growing demand for Torx screws at the 138th Canton Fair in 2025 highlights a significant shift in consumer preferences that is driving market expansion. As industries seek more reliable and efficient fastening solutions, the unique design of Torx screws, which offers superior grip and torque, has captured the attention of manufacturers and end-users alike. This trend is particularly evident in automotive, electronics, and construction sectors, where the reliability of fastening components is paramount.

Moreover, the increasing awareness of quality and performance among consumers is contributing to the rising popularity of Torx screws. Buyers are now more inclined to invest in products that provide durability and ease of use, leading them to favor Torx screws over traditional fasteners. As manufacturers continue to innovate and expand their offerings, including variations in size and material, the market is poised for further growth. The emphasis on quality-driven choices among consumers is set to shape the future landscape of the Torx screw market, reinforcing its relevance in a competitive industrial environment.

Sustainability Practices in Torx Screw Production and Global Impact

The growing demand for Torx screws, particularly highlighted during the 138th Canton Fair in 2025, is increasingly intertwined with sustainability practices in their production. Recent industry reports indicate that the global screws market is expected to reach $7.09 billion by 2027, with a significant portion attributed to the rising preference for Torx screws due to their enhanced torque and reduced risk of stripping. Manufacturers are recognizing the importance of aligning their production methods with sustainable practices not just for compliance but also to meet consumer demands for environmentally responsible products.

In terms of sustainability, companies are adopting green manufacturing processes, including the use of recycled materials and energy-efficient production techniques. A report from Smithers Pira highlights that up to 30% of the materials used in screw manufacturing can be recycled, which contributes significantly to reducing the carbon footprint of the manufacturing process. Additionally, more suppliers are investing in technology to minimize waste and improve energy efficiency, reflecting a broader trend in the fastener industry towards sustainability. This shift not only enhances brand reputation but also appeals to an increasingly eco-conscious market, ultimately driving further growth in the Torx screw segment.

Exploring the Growth of Torx Screw Demand at the 138th Canton Fair China 2025: Insights and Trends - Sustainability Practices in Torx Screw Production and Global Impact

| Region | 2023 Demand (Million Units) | 2025 Projected Demand (Million Units) | Sustainability Initiatives | Recycling Rate (%) |

|---|---|---|---|---|

| North America | 15 | 20 | Use of recycled steel | 60 |

| Europe | 25 | 30 | Circular manufacturing processes | 70 |

| Asia-Pacific | 30 | 45 | Energy-efficient production | 65 |

| Latin America | 10 | 15 | Sustainable sourcing of materials | 50 |

Related Posts

-

Understanding the Importance of Torx Screws in Modern Engineering

-

How to Select the Perfect Button Head Bolt for Optimal Load Distribution in Your Projects

-

How to Choose the Right High Tensile Carriage Bolt for Your Project Needs

-

How to Choose the Perfect Hot Sale Carriage Bolt for Your Project

-

The Ultimate Guide to Choosing the Right Furniture Screw for Your Projects

-

5 Essential Tips for Choosing the Right Truss Head Carriage Bolt for Your Project